Real-time tools, including computer vision and Augmented Reality (AR), are transforming car body shop operations by enhancing repair quality inspection. These technologies provide mechanics with immediate, precise data, reducing errors and increasing efficiency. Integration improves accuracy and quality control, ensuring vehicles leave the shop in excellent condition. However, challenges like internet connectivity and staff training must be addressed through comprehensive training programs and clear protocols to maximize these tools' benefits.

In today’s fast-paced manufacturing landscape, ensuring accurate repair quality inspection is paramount for maintaining high production standards. Real-time tools have emerged as game-changers, revolutionizing traditional inspection methods with enhanced precision and efficiency. This article delves into the critical role of real-time technologies in streamlining repair quality inspections, exploring common technologies, best practices, and challenges encountered during implementation. By understanding these aspects, manufacturers can harness the power of real-time tools for consistent, top-quality results.

- Understanding the Importance of Real-Time Tools in Repair Quality Inspection

- Common Real-Time Technologies for Enhanced Accuracy in Inspection Processes

- Best Practices and Challenges in Implementing Real-Time Tools for Consistent Quality Results

Understanding the Importance of Real-Time Tools in Repair Quality Inspection

In today’s fast-paced automotive industry, real-time tools have become indispensable for ensuring accurate and efficient repair quality inspection in car body shops. These innovative technologies go beyond traditional methods, providing mechanics with precise data and immediate feedback during the repair process. By integrating real-time systems, car body restoration professionals can significantly enhance their work’s accuracy and consistency.

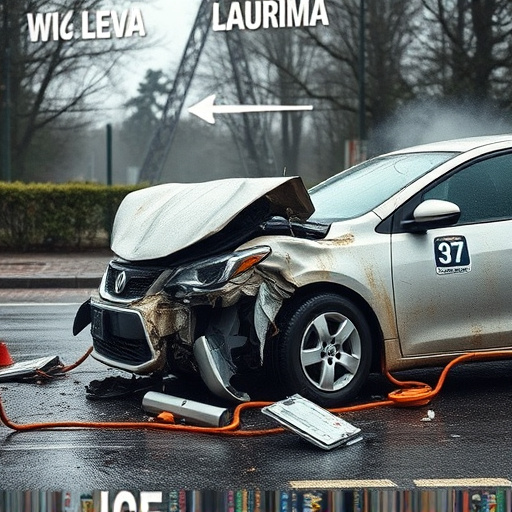

This shift is particularly notable in car repair services, where minimizing errors and maximizing efficiency are key to customer satisfaction and business success. Real-time tools enable inspectors to detect even subtle defects or inconsistencies instantly, preventing them from going unnoticed during manual inspections. As a result, these technologies foster a culture of quality assurance, ultimately leading to better-repaired vehicles and enhanced reputation for car body shops.

Common Real-Time Technologies for Enhanced Accuracy in Inspection Processes

The advancement of real-time technologies has significantly boosted the accuracy and efficiency of repair quality inspection processes in both auto frame repair and vehicle body shop settings. One of the most prominent tools is computer vision, which uses cameras and algorithms to detect defects on surfaces with remarkable precision. This technology ensures that every dent, scratch, or misalignment is captured and analyzed in real-time, enabling technicians to make informed decisions during car paint services.

Additionally, Augmented Reality (AR) has found its way into the repair quality inspection arena. AR overlays digital information onto a vehicle’s physical structure, providing inspectors with a clear view of potential issues and exact measurements. This technology is particularly useful in complex auto frame repair scenarios, where precise alignment and structural integrity are paramount. Real-time data synchronization ensures that any adjustments made during the repair process are instantly reflected, enhancing overall accuracy and quality control in vehicle body shops.

Best Practices and Challenges in Implementing Real-Time Tools for Consistent Quality Results

Implementing real-time tools for repair quality inspection aims to enhance accuracy and consistency in automotive repair and car body restoration processes. However, embracing these technologies comes with unique challenges. One of the primary hurdles is ensuring reliable internet connectivity at the work site, especially in shops dealing with body shop services, where wireless signals might be inconsistent or non-existent.

Another challenge lies in training staff to effectively utilize real-time tools. Technicians accustomed to traditional methods need time and guidance to adapt to digital systems, learning not only the technical aspects but also understanding how these tools can streamline their work without replacing their expertise. Best practices include providing comprehensive training programs, establishing clear protocol for tool usage, and fostering a culture of continuous improvement to maximize the benefits of real-time technology in achieving consistent quality results.

Real-time tools have emerged as indispensable assets in the realm of repair quality inspection, revolutionizing how we approach precision and accuracy. By leveraging cutting-edge technologies, such as computer vision and sensor fusion, professionals can now navigate complex repairs with enhanced efficiency and consistency. However, successful implementation demands careful consideration of best practices and addressing challenges like data integration and user training. As these tools continue to evolve, they promise to further refine the repair quality inspection process, ultimately fostering higher standards across various industries.