Repair Quality Inspection (RQI) is a critical process ensuring vehicle safety and quality post-damage. It involves detailed assessments of structural integrity, mechanical systems, and collision repair/auto painting. RQI's Safety System Verification includes advanced tools for analyzing structural integrity, active/passive safety features, and enhancing peace of mind. Best practices like training, standardization, and automated testing are essential due to complex automotive technology. Feedback loops facilitate knowledge sharing and continuous improvement, ensuring consistent safety standards across all repairs, from simple to advanced systems.

In today’s world, ensuring safety through robust repair quality inspection (RQI) is paramount. This article delves into the intricacies of RQI, focusing on the fundamental concepts and key components that constitute a comprehensive safety system verification process. We explore the challenges encountered during verification and offer best practices to enhance accuracy and efficiency. By understanding these aspects, stakeholders can uphold higher standards in repair quality inspection, ultimately fostering safer environments.

- Understanding Repair Quality Inspection Basics

- Key Components of Safety System Verification

- Challenges and Best Practices in Verification

Understanding Repair Quality Inspection Basics

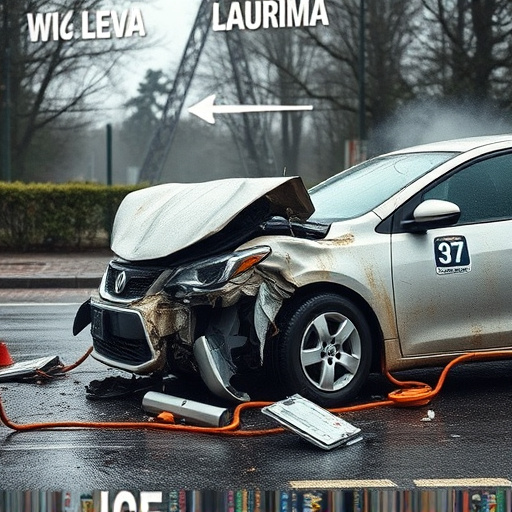

Repair Quality Inspection is a critical process that ensures the highest standards in vehicle maintenance and restoration. It involves a thorough evaluation of vehicles, particularly after accidents or significant structural damage, to assess their condition and suitability for rebuilding or resale. This meticulous inspection goes beyond visual appraisals; it encompasses a comprehensive review of various components, including chassis, mechanical systems, and finishes like collision damage repair and auto painting.

The primary goal is to verify the integrity and safety of the vehicle, ensuring that any repairs conducted adhere to industry standards and regulations. Skilled inspectors utilize specialized tools and knowledge in automotive restoration to detect even subtle defects or discrepancies. By implementing rigorous repair quality inspection protocols, mechanics can guarantee not only the structural soundness of vehicles but also provide assurance to consumers who value safety and quality in their transportation means, be it through collision damage repair or extensive auto painting services.

Key Components of Safety System Verification

The key components of Safety System Verification in Repair Quality Inspection are intricately designed to ensure that every auto body repair and restoration process adheres to the highest safety standards. This involves a multi-faceted approach that starts with a comprehensive analysis of the vehicle’s structural integrity, focusing on critical systems such as frames, suspension, and brakes. By employing advanced diagnostic tools, experts in autobody repairs can identify even subtle discrepancies or damage not visible to the naked eye.

Moreover, safety system verification encompasses the meticulous inspection of all components related to active and passive safety features, including airbags, seatbelts, collision detection systems, and crumple zones. In an automotive body shop, these checks are vital to guarantee that each repair not only restores aesthetic appeal but also maintains or enhances the overall safety functionality of the vehicle. This holistic approach ensures that every auto maintenance task, from minor fixes to extensive restructuring, meets stringent safety criteria, ultimately enhancing the peace of mind for drivers and passengers alike.

Challenges and Best Practices in Verification

The process of Safety System Verification in Repair Quality Inspection is fraught with unique challenges. Ensuring the reliability and safety of vehicle systems, particularly in complex modern cars, demands meticulous attention to detail. Every component, from advanced driver-assistance systems (ADAS) to structural integrity, must be accurately assessed for potential failures or inconsistencies during repairs. One significant hurdle is the constant evolution of automotive technology, requiring inspection personnel to stay abreast of new system configurations and repair procedures.

To overcome these challenges, best practices emphasize continuous training and standardization. Utilizing industry-approved protocols and reference materials guarantees consistent verification methods across different car repair shops. Automated testing tools can significantly enhance efficiency in tasks like checking for airbag deployment mechanisms or auto glass replacement quality. Moreover, implementing a robust feedback loop system enables the documentation and sharing of findings, fostering an environment where lessons learned are applied to improve overall repair quality, be it for a bumper repair or more intricate systems. This collaborative approach ensures that safety standards are met and maintained, ultimately enhancing customer trust in the repair process.

Safety System Verification plays a pivotal role in ensuring the integrity and reliability of repair quality inspections. By meticulously assessing key components and adopting best practices, we can overcome challenges and enhance overall repair precision. A robust verification process not only safeguards against potential hazards but also instills confidence in the inspection results, ultimately contributing to improved vehicle safety on the road.